The Aerospace and Transportation Materials and Manufacturing (ATMM) pillar primarily conducts research in the following areas: additive manufacturing, automation and control for automotive applications, defect characterization of engineering materials via 3D X-ray imaging, multi-phase flow: applications and fundamentals, material joining/welding techniques, mathematical modelling (FEA/CFD) of manufacturing processes, multi-scale modelling of structure-processing-properties relationships, structural health monitoring of processes and structures, thermo-chemo-mechanical characterization of lightweight alloys and composite materials, and thermal management and cooling technologies for power electronics.

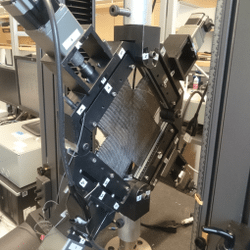

Combined bi-axial and shear testing of a woven composite (courtesy of Dr. Ababs Milani).

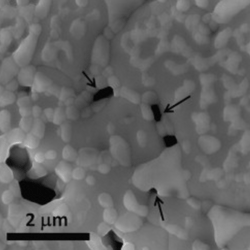

Creep-induced void nucleation in a ceramic composite (courtesy of Dr. Lukas Bichler).

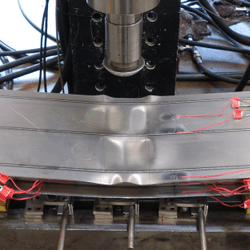

Three-point bending testing of a sandwich beam (courtesy of Dr. Jasmin Jelovica).

Research Highlights

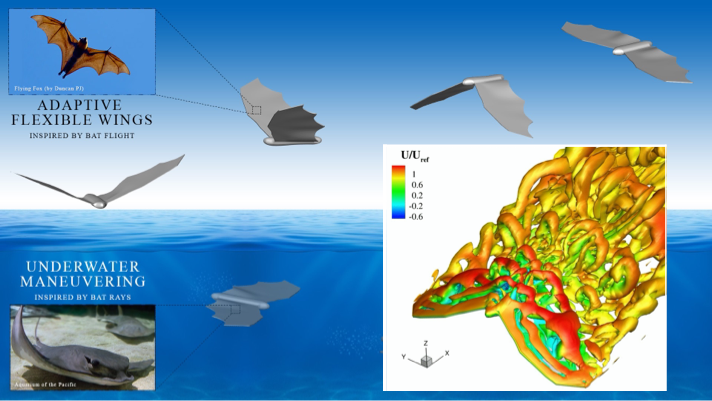

Birds such as bar-tailed godwits fly nonstop from Alaska to Australia while utilizing only a small amount of energy and navigating by unknown means. An aerial swarm of bats and birds maintains their trajectories and coordination with complex physical interaction. Flying bats can catch their prey in the dark with high precision. Within the theme of “breaking barriers of the impossible,” we present some research highlights of our in-house framework towards the development of futuristic bio-inspired intelligent and green flying vehicles. The framework emulates the natural flyers in the spirit of model, sense, learn and control by integrating various aspects of computational multiphysics with biology and artificial intelligence. The key component of the framework is to leverage high-fidelity physics-based modelling together with deep-learning-based reduced-order models. Finally, we provide some research directions towards the development of a physics-based digital twin of small-size flying vehicles.

Learn more about this research project Here.

Leads

Dr. Rajeev Jaiman

Associate Professor

Department of Mechanical Engineering

Vancouver Campus

rjaiman@mech.ubc.ca

Webpage

Dr. Mohammad Arjmand

Assistant Professor

School of Engineering

Okanagan Campus

mohammad.arjmand@ubc.ca

Webpage

Cluster News

May 08, 2019

Researchers are aiming to ease that winter frustration with a new surface coating that can shed ice from large areas using little effort.

Mar 20, 2019

By mixing carbon fibres into polymer-based brakes, researchers were able to design brakes that are self-lubricating.

Oct 17, 2018

UBC researchers are investigating new technologies that are making high-tech surveillance faster and more effective.

Jun 08, 2018

Fusing welding is a generic term for welding processes that rely on melting to join metals with similar compositions.

May 08, 2018

UBC engineers iron out the wrinkles in producing strong and durable materials.

May 07, 2018

UBC is developing — in conjunction with the Composites Research Network and its industrial partners — an exciting new initiative to reimagine composites manufacturing for the 21st century, bringing together simulation, sensors and data analytics, and automation.